specifications.

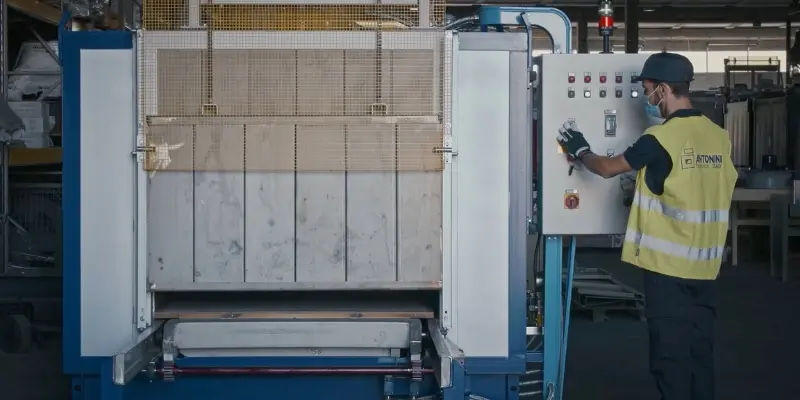

Mold Pre-heating Lehr

Optimization of the molding process with the same Antonini technology

Mold Pre-heating Lehr

Our Mold Pre-heating Furnaces (MPF), use the same components as the other Antonini furnaces, represent the ideal solution to optimize the quality of castings and maximize the efficiency of the production cycle. Developed to ensure uniform heat distribution and precise temperature control, our MPF are available in both standard versions and customized configurations, designed to perfectly suit every specific operational need.

REQUEST INFO -> DOWNLOAD THE CATALOGEnergy Efficiency

With over seventy years of research and innovation, thanks to the thermal insulation of our furnaces and the technical design of Antonini burners, we have achieved an unprecedented level of energy efficiency. This progress has allowed us to drastically reduce energy consumption, setting a new standard in the field of efficiency and energy sustainability

Accessory Solutions for High-Quality Productions

The Antonini product range includes Mold Pre-Heating Furnaces (FPS), accessory devices but often indispensable for efficient production processes. These furnaces are primarily used for:

Preheating of molds, essential to ensure optimal glass processing.

Specific thermal treatments on equipment such as slides, molds, and other essential components in the glass processing process.

Stand-alone Mode

FPS furnaces in Stand Alone mode are small heated chambers, equipped with mechanical movement systems such as single or multi-level extractable trolleys and single or double doors. We offer both standard models and customized solutions, designed to meet specific customer needs. These furnaces are built using components similar or interchangeable with those of Antonini Annealing Furnaces, to minimize the need for specific spare parts.

Built-in Mode

FPS furnaces in Built-In mode are integrated directly into the side walls of zones 2 or 3 of the Annealing Furnaces. Accessible via highly insulated doors with individual closures, these spaces are optimized for maximum energy and space savings. Choosing this system is ideal in situations where the potential for integration can be best utilized, offering practical and efficient solutions in the production process.

IMMEDIATE PROJECTS, REAL RESULTS

For direct contact