specifications.

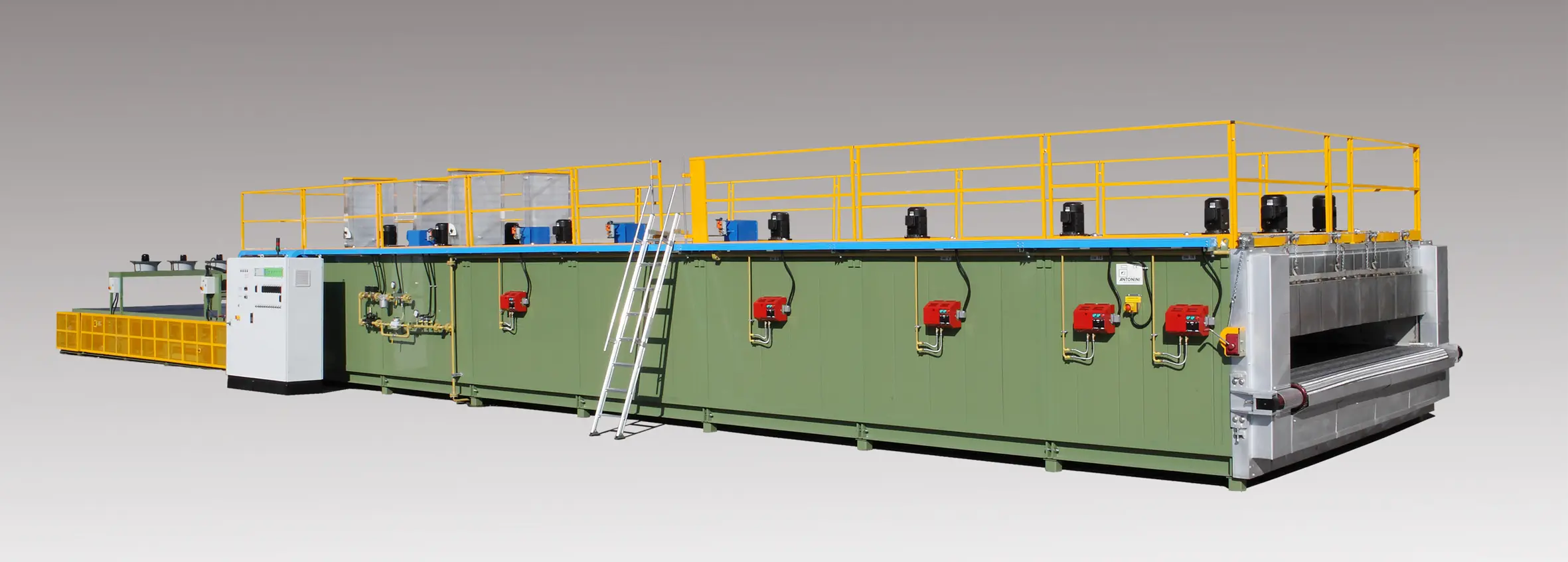

Annealing Lehr

Efficiency and precision in the glass annealing process

Annealing Lehr

Antonini's Annealing Furnaces are engineering masterpieces, designed to perfect the quality of glass. Each furnace is a blend of advanced technology and artisanal precision, ensuring excellent results in the annealing process. The furnaces optimize the stability of the glass and reduce internal stresses, significantly contributing to the quality of the final product

REQUEST INFO -> DOWNLOAD THE CATALOGEnergy Efficiency

With over seventy years of research and innovation, thanks to the thermal insulation of our furnaces and the technical design of Antonini burners, we have achieved an unprecedented level of energy efficiency. This progress has allowed us to drastically reduce energy consumption, setting a new standard in the field of efficiency and energy sustainability

Entry section

The Antonini Annealing Furnace offers a sophisticated and technologically advanced entrance. This includes an anti-deformation roller, designed to self-compensate for thermal elongation and ensure impeccable stability. The roller support system ensures a smooth transition of glass into the first module of the tunnel, preventing any sagging of the conveyor belt. The 'sandwich' door, easily liftable manually or through motorization, minimizes thermal dispersion. On request, we offer a covering for specific needs and, in case of manual loads, we integrate pneumatic doors for optimized management.

Temperature-controlled section

The Antonini Annealing Tunnel is configured with custom modules, determined by production, loading system, temperatures, and thermal process. We offer three types of modules: heating, mixed (heating and cooling), and cooling. Each module consists of an internal stainless steel box, rock wool insulation, and external paneling, customizable in color and materials, including stainless steel. The interiors are equipped with air recirculation systems for uniform temperature, burners or electric resistances, fresh air valves, and exit chimneys in the cooling area. The heating power is strategically distributed, adaptable to different types of glass and special treatments. Strategic thermocouples detect the temperature, ensuring the system's efficiency. The tunnel exit includes manual or motorized doors.

Uncovered section and towing group

The external section of the Antonini furnace is built with robust frames, suitable for the load. It includes a conveyor belt traction system with gearmotor, chain transmission, and various rollers for belt deviation. It features a mechanism for the recovery of belt elongation and continuous tension, as well as a system for adjusting its direction. The area is equipped for cold treatments, such as vaporizing hoods and sprays, space for auxiliary cooling batteries, and a belt cleaning system (motorized brush). This design is studied to prevent slippage of the belt under any load condition.

IMMEDIATE PROJECTS, REAL RESULTS

For direct contact